Environmental Commitment

HELPING THE WORLD TO BE MORE SUSTAINABLE

AERONAUTICAL MARKET

For several years now, the transportation industry has been modernizing and mobilizing to fight against global warming.

Civil aviation represents 2% of total CO2 emissions, and 13% of public transport emissions. The aviation industry, under the aegis of the ICAO (International Commercial Aviation Organization), is the first economic sector to adopt a universal and binding global system to control its CO2 emissions, known as CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation).

The International Air Transport Association (IATA) has approved a resolution for the global airline industry to achieve zero net carbon emissions by 2050. This commitment will align with the Paris Agreement’s goal of no more than 1.5°C of global warming. “Airlines around the world have made a momentous decision to ensure that flying is sustainable. The post-COVID-19 reconnection will be on a clear path to net zero. This will ensure the freedom of future generations to explore, learn, trade, create markets, enjoy cultures and connect sustainably with people around the world. With the collective efforts of the entire value chain and supportive government policies, aviation will achieve net zero emissions by 2050 “, said Willie Walsh, IATA Director General.

MICHELIN GROUP COMMITMENT

The world is changing rapidly, and our environment and natural resources are under threat. To ensure its long-term growth, a company must be able to place human, economic and environmental issues at the center of its decisions.

The All Sustainable approach is integrated into the Group’s strategy based on a balanced development between People, Planet and Economic Performance. On this holistic basis, Michelin is innovating and committing itself more than ever to a life in motion.

In 2022, Michelin is taking a new step forward by translating its All-Sustainable approach into ambitions for 2030 and beyond.

MICHELIN AIRCRAFT COMMITMENT

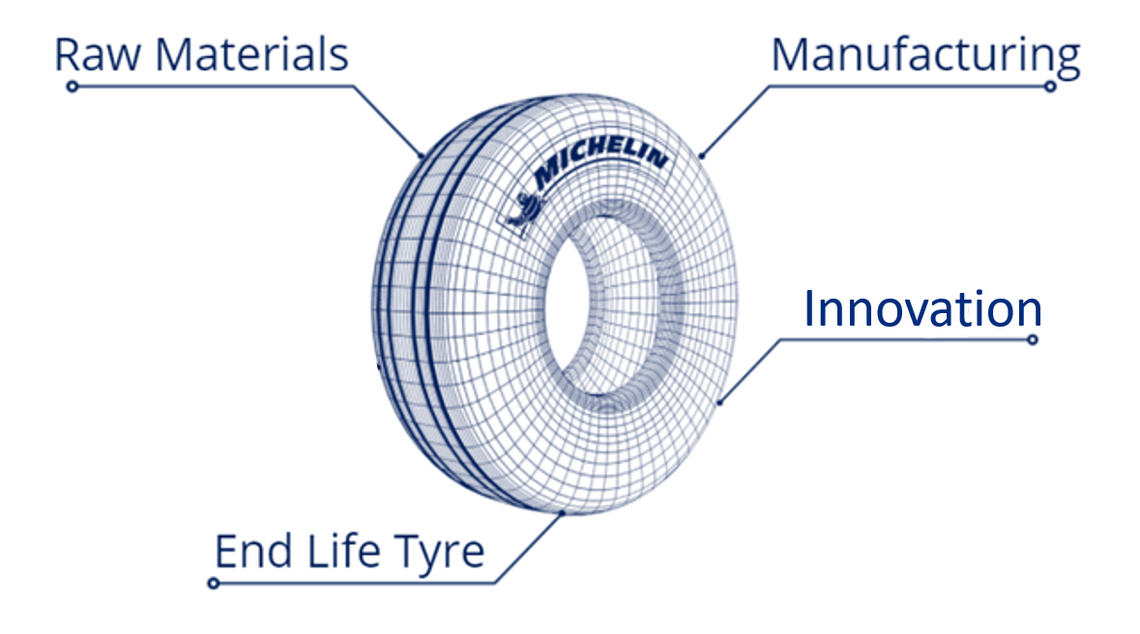

Michelin Aircraft is strongly committed to contribute to improve sustainable development.

To meet these challenges, we take the entire life cycle into account when designing our tires (life cycle analysis approach).

The ultimate goal is to be carbon neutral by 2050, as announced by the Group.

For more information, please visit Michelin Sustainable Development and Mobility

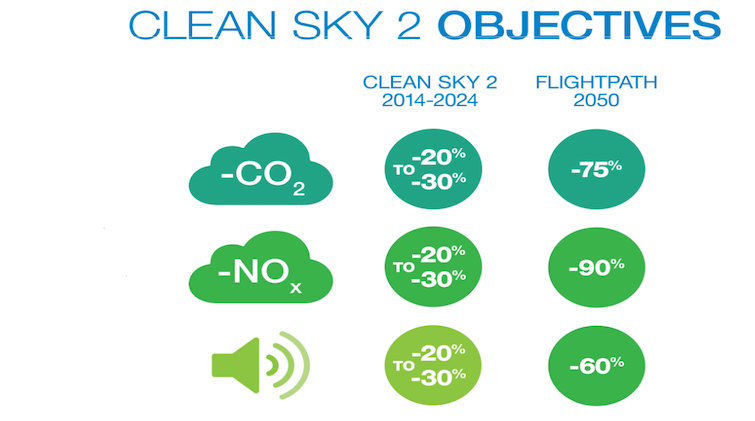

WHAT IS CLEAN SKY 2 ?

Clean Sky 2 is the European Research Program, which is part of Horizon 2020. The core mission of Clean Sky 2 is to develop breakthrough technologies to significantly increase the environmental performance of aircraft and also aims to contribute to European competitiveness and mobility.

HOW DOES MICHELIN CONTRIBUTE TO THIS PROGRAM ?

In the Clean Sky 2 Advanced Landing Gears demonstrator, in partnership with Safran, Michelin studied new technologies and developed innovations, including weight reduction, which is a major stake for aircraft manufacturers and airlines.

RAW MATERIALS

Today, on average, more than 40% of the materials used to produce our tires is of sustainable origin (recycled or renewable). In addition, we provide our customers with an application, Rubberway, aimed at improving the whole supply chain and training around natural rubber.

MANUFACTURING SUSTAINABILITY: NORWOOD

Emissions

Eliminate heavy fuel and replace by natural gasProject to eliminate waste burning.

Reduce amount wastes by 94% in 2020.

Find other usage example : tires retread into farmer / industrial tires uncured rubber turned into as rubber mallets and trucks “mud flaps”.

MANUFACTURING SUSTAINABILITY: BOURGES

Use of renewable energy : Biomass (wooden wastes) to replace fossil fuels (85% of plant energy source)

Purchase of Green energy.

Optimization of water use.

Change of all neon lights by leds = big electricity saving.

Project to turn scrap tires into other usages (ex: running track) or transform wastes into energies.

Sorting out and recycling of raw materials.

8 to 9 beehives on site: one honey pot per employee per year (200Kg produced each year)

Establishment of orchards composed of endemic species.

MANUFACTURING SUSTAINABILITY: NONG KHAE

Solar energy: Solar panel.

Roof ventilation to reduce electric fan.

Electric press instead of steam to cure tires.

Plastic bags and poly in production.

Reduce waste from office, canteen.

Scrap tire (100% recycled) turned into oil, metallic wire, carbon black.

Poly and plastic bags.

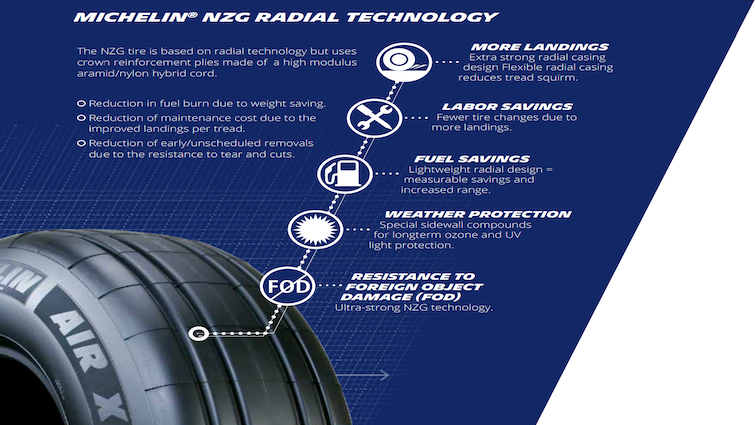

INNOVATION

Innovations in our tires make them ever safer, more efficient and more environmentally friendly. Innovation is the DNA of Michelin Aircraft products. The technical challenges are very strong. Michelin has always proposed breakthrough innovations in aircraft tires. Michelin invented the Radial tire in 1946 and then gradually extended it to aircraft tires. The first radial aircraft tire was introduced in 1981, a solution that is now widely used in commercial aviation. Michelin also introduced a new revolution in aircraft tires in 2001 with the NZG (Near Zero Growth). It is still a radial tire, but it uses innovative reinforcements to reduce the tire’s weight while increasing wear life and improving safety. The MICHELIN NZG has since been adopted on many commercial aircraft, and in particular on new generation aircraft such as the Airbus A350. The use of an NZG tire compared to a Bias tire saves an average of 20 kg per tire* and more, for a total saving of 85 to 150 kg depending on the aircraft type. This can represent a reduction of 9 to 16 kg of CO2 emissions per flight hour. The reduction is therefore extremely significant on the scale of the number of daily flights.

TYRE END OF LIFE

Our role does not end with the use of our tires.

Indeed, at Michelin Aircraft we take into account the end of life of our tires as entire part of our life cycle analysis.

This is why we have built local partnerships to ensure the recycling or reuse of tires at the end of their life.

In Europe, Aliapur holds this responsibility and reuses the tires in different applications such as: athletics track, road slowing system, archery targets…We therefore guarantee that all the tires that our customers return to us are either reused or recycled. This commitment allows us to build a circularity of our products and to commit ourselves sustainably to the environment.